Treadle pumps

Practical Action

Main Highlights

• High water output

• Easy to operate

• Affordable

• Appropriate and attractive to smallholders

• Zero fuel cost for operation

• Can be installed locally

• One year warranty

Suitability and Cost for Installation

a) Recommended depth of pumping: up to 22 ft

(exceptionally up to 25 ft)

b) Water Discharge: 0.8 - 1.0 litres per second

(depends on the depth of water and power of the

operator)

c) Irrigable Land by one pump: 2000-3000m2

(depends on soil type and aquifer type)

d) Size of the tube well: 1.5 Inch

e) Cost of Installation under sludger drilling at a

depth of 40 ft

• Pump head: $9

• Pipe & Filter: $20

• Installer’s Service fee: $ 8

• Local materials / labour: $ 6

Total: $43

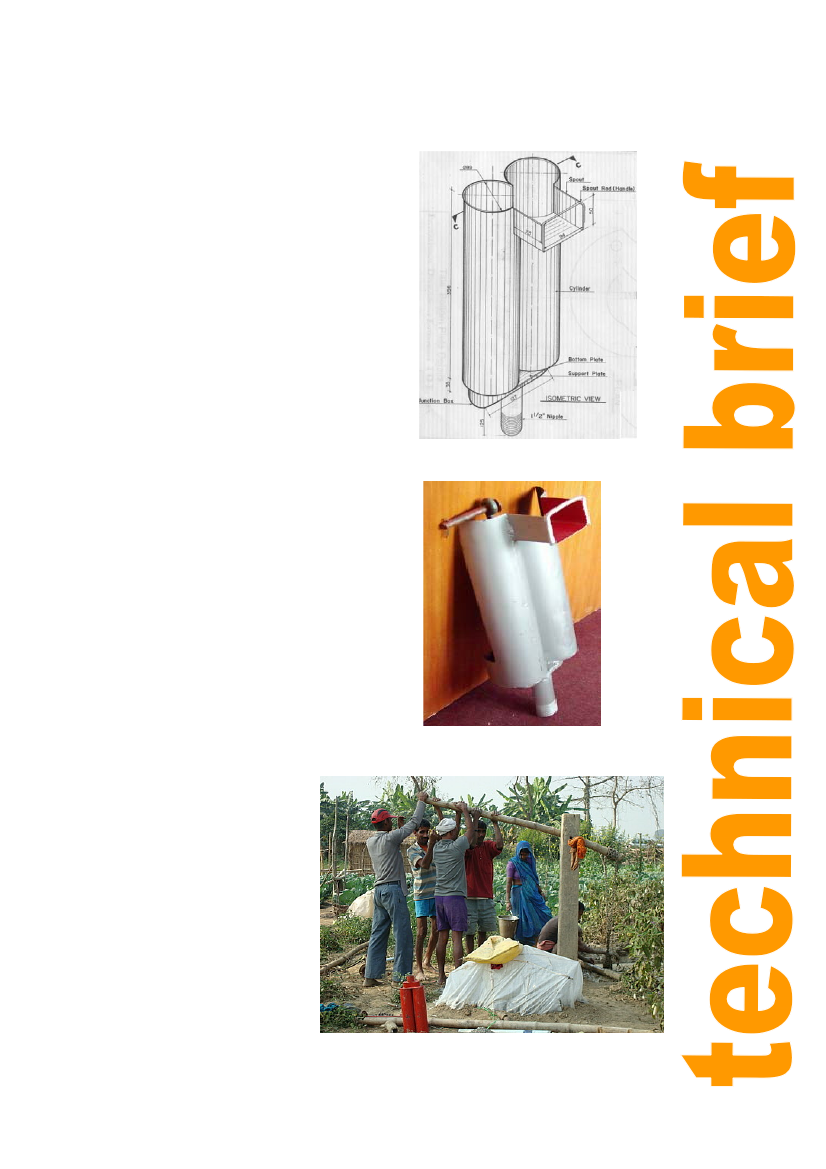

Figure 5: The piston design.

f) Operation and Maintenance cost: $ 0.8 per year.

Technical Components

The completely installed treadle pump has essentially three

parts.

a) Pump head with Piston set

b) Superstructure and

c) Tube-well pipe with filters

The pump head consists of a twin barrel connected by a

junction box in one end. The barrels are made of a 16BG,

16 Imperial Gauge (1.63mm) or

equivalent mild steel sheet metal. A

check valve is housed at the bottom of

the cylinder. The piston set is made of

10mm diameter mild steel rod which

has two round discs at one end kept

10mm apart by a PVC bucket washer

which is housed between the discs.

The other end of the rod is connected

with the treadle.

Figure 6: The fabricated cylinder.

The superstructure is erected by using

bamboo or wooden poles. It consists of

two horizontal pedals and two vertical

poles as shown in the picture. A dwarf

pole (Guide) is installed between the

pedals to prevent the collision of

pedals. For tubewell the most are most

Figure 7: Farmers, from Mainhiya Village Development

Committee, installing a treadle pump for irrigation. Photo:

Practical Action Nepal / Matrika Sharma.

3